Geothermal Green House Prototype

The geothermal greenhouse prototype stage 1 is completed at our Vermont Research Farm!

Key Features

Innovative Design: Renewably-powered in-earth 4-season greenhouse combined with a root cellar.

Geothermal Integration: Vented, heated, and cooled using geothermal air pipes and water-to-air ground source heat pumps.

Durable & Low-Maintenance: Emphasis on long-term resilience and minimal upkeep.

High Energy Efficiency: Potential to achieve 500% energy efficiency.

Versatility: Can be used alternatively as housing or emergency shelter.

Open-Source Model: Encourages replication, scaling, and modification across varied locales.

Low-Cost and Practical: Can be easily and cheaply reproduced

The core idea is to fuse age-old techniques with modern technology. By integrating a renewably-powered in-earth greenhouse with geothermal systems, we aim to improve options in accessible food production and storage. This not only maximizes our energy efficiency, but also offers a design meant to last with minimal maintenance, which can be easily built and replicated to enable localized 4 season growing of high value crops (for example local fruit in the winter without any need for fossil fuel inputs).

Given its inherent stability and temperature control, this infrastructure can double as housing or even emergency shelter. This duality offers exciting possibilities for communities, especially in regions with extreme weather conditions.

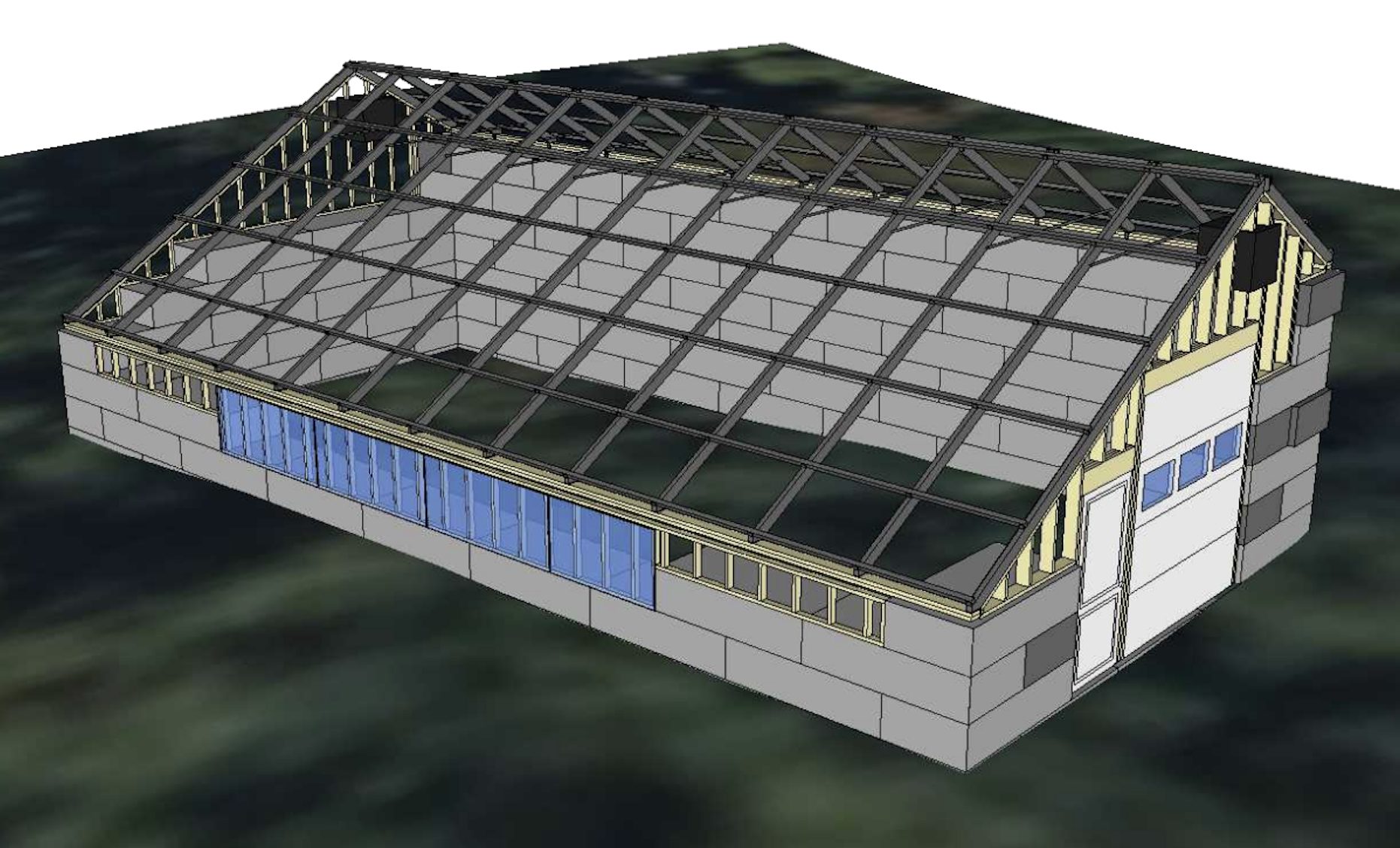

Design

This greenhouse design features a 42' x 24' interior space built with substantial 6' x 3' x 1.5' concrete blocks set directly on compacted crushed stone (no concrete footings required). A key innovation is the massive geothermal heat storage system behind the back wall - ~2,000 cubic feet of crushed stone with air circulation pipes, insulated with 5" foam panels - which stores and releases heat to maintain stable growing temperatures. The total investment of $82,819 (built in 2024) can yield 2,350-4,000 pounds of fresh produce annually when growing multiple crops concurrently, based on conservative calculations using industry-standard yields. This design demonstrates the potential for reliable performance even in harsh winter conditions, with the geothermal system maintaining viable growing temperatures year-round. The combination of thermal mass storage and protected growing space creates an efficient environment that maximizes both natural resources and growing space for sustainable food security.

Construction Progress: Phase 1

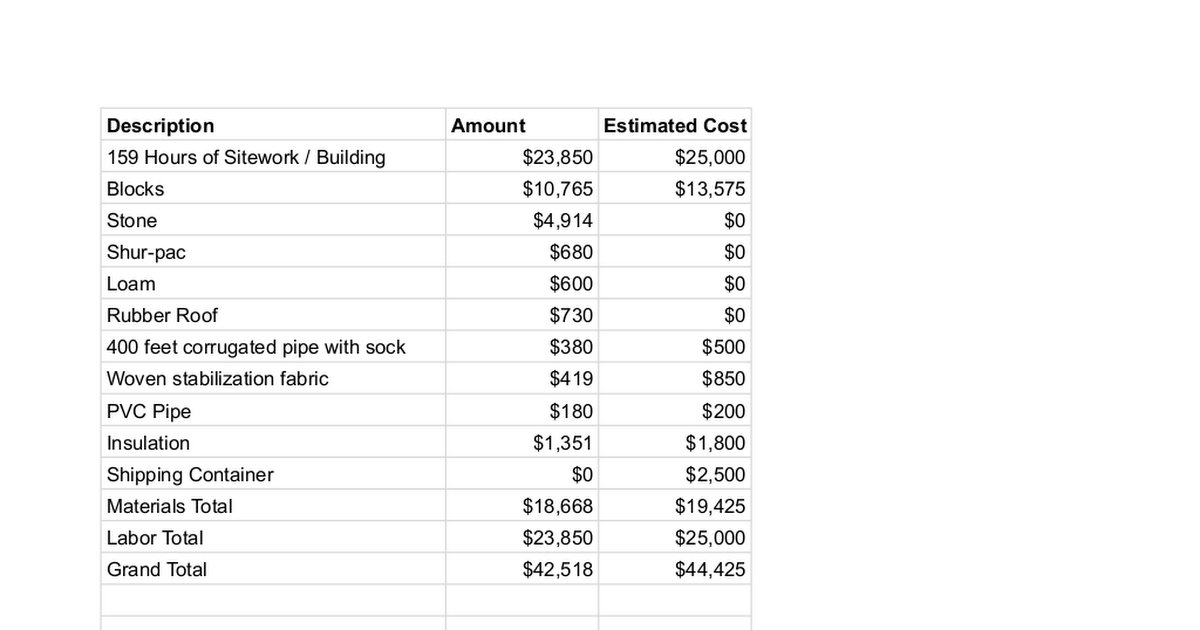

The total actual cost thus far is about $43,000, which is near the target of the estimated $45,000 spent so far. (These numbers are slightly higher than in the spreadsheet due to a few smaller items not being accounted for yet). Construction of phase 1 was completed in 16 days with 2 people (one operating a large excavator). Based on lessons learned so far, this time could likely be reduced by 20-40%.

The concrete shell and air-to-air geothermal system have been successfully installed. The system includes 300 feet of line running through over half a million pounds of thermal mass in the form of crushed stone and concrete wall. The entire structure is surrounded by 5 inches of styrofoam insulation to store thermal energy in the battery. Initial tests indicate signs of success, but additional testing will be needed on more extreme heat/cold days. The root cellar has also been constructed with ventilation systems and compatibility with HEPA air filtration.

Below you can see our cover crop put in the greenhouse base before winter.

And here is a full set of photos from construction..

Photos of the prototype and construction

As well as the CAD plans

Prototype Greenhouse Design in Sketch-up

And Costs spreadsheet

Cost Breakdown of Vermont Prototype

Detailed below are the actual costs for a 42' x 24' in-ground off-grid geothermal greenhouse designed for Vermont climate that was started in 2024 for approximately $85,000 including all materials and labor. This design includes galvanized steel and is designed to last an extremely long time. ~$10-15k can be saved with a more traditional design using pressure treated lumber to last several decades. The table below provides the detailed cost breakdown (italicized are estimates):

Labor Breakdown

- Initial excavation, block placement, and geothermal battery construction: 300 man-hours total

- Includes excavating 1,764+ cubic feet for geothermal mass

- Placing and compacting crushed stone

- Installing corrugated pipe network

- Setting concrete blocks on compacted stone base (no concrete footings)

- Building root cellar if included

- Requires heavy equipment (excavator rental with experienced operator needed)

- Roof steel structure installation: Additional 80-100 man-hours

- Can be completed within a week once steel is fabricated

- Other materials (wood) could be used for much lower cost (though sacrificing longevity)

- Total labor: Approximately 400-450 man-hours

Cost Notes

- Stone: $4,914 covers ~2,000 cubic feet of crushed stone for the geothermal thermal mass

- Corrugated pipe: $380 for 400 feet of perforated pipe with sock filter, runs through the stone mass for air circulation

- Polycarbonate panels: Estimated at $3.50/sq ft for 10mm twin-wall panels (approximately 1,000 sq ft needed)

- Insulation: The $1,351 covers 5" polystyrene foam panels for the geothermal mass enclosure

- Regional labor costs vary significantly - expect 20-30% variation between regions

- Materials costs reflect 2024 pricing

Physical Footprint & Siting Requirements

The greenhouse has an interior footprint of 42 ft x 24 ft (1,008 ft²). The structure is built using concrete blocks measuring 6' long x 3' deep x 1.5' thick, creating (very)substantial thermal mass for temperature regulation (amplified by additional massive mass of crushed stone in the battery itself).

Geothermal System Requirements

Behind the back wall is a massive geothermal heat air transfer system consisting of:

- Crushed stone thermal mass: 42' x 3' x 14' (~2000 cubic feet)

- Corrugated pipe: Running through the stone mass for air circulation

- Insulation: 5" thick polystyrene foam panels surrounding the entire system

Total Space Requirements

- Interior growing space: 42' x 24'

- Exterior structure footprint: ~48' x 30' (accounting for 3' thick walls)

- Geothermal system adds: ~3' depth plus insulation behind back wall

- Total footprint needed: ~55' x 35' minimum

- Recommended site area: 65' x 45' for adequate access and maintenance

Optimal Siting

- Solar orientation: Long axis running east-west with south-facing glazing for maximum winter sun capture

- Slope: South-facing slope ideal for natural drainage and earth berming opportunities

- Geothermal mass placement: The back (north) wall requires 3' additional depth plus insulation space for the thermal mass; building into a hillside is necessary.

- Protection: Natural windbreak to north/northwest; avoid tall trees on south side

- Access: Proximity to power source and water supply; vehicle access for material delivery

Drainage: Well-drained site essential; avoid low spots where water collects

Project Timeline

DIY Build Timeline

- Planning & Permitting (4-8 weeks)

- Design finalization and material sourcing

- Permit applications where required

- Equipment rental scheduling

- Site Preparation (1-2 weeks)

- Excavation and grading

- Excavate area for geothermal mass (42' x 3' x 14' deep)

- Drainage installation

- Foundation & Block Work (1-2 weeks)

- Compact crushed stone base layer

- Set first course of blocks directly on compacted stone

- Build walls with 6' x 3' x 1.5' concrete blocks

- Simultaneously construct geothermal battery:

- Place and compact 1,764 cubic feet of crushed stone

- Install corrugated pipe through stone mass

- Enclose with 5" foam insulation panels

- Backfill and bury lower portions as construction progresses

- Structure Assembly (1-2 weeks)

- Steel roof framework installation (1 week once fabricated)

- Install purlins and bracing

- Mount polycarbonate panels

- Frame and side end walls

- Systems Installation (1-2 weeks)

- Connect geothermal air circulation fans to corrugated pipes

- Install intake and exhaust plenums for geothermal mass

- Basic electrical work

- Ventilation systems

- Test air circulation through stone mass

- Interior Finishing (2-3 weeks estimate)

- Build growing beds

- Install irrigation

- Final systems testing

Food Production Estimates

Based on industry-standard yields and conservative calculations, a well-managed 1,000 ft² greenhouse can produce 2,350-4,000 pounds of food annually through mixed cropping. The geothermal system enables year-round production even in challenging climates.

Typical Mixed Production Layout

In the 1,008 ft² interior space, a practical layout might include:

- 30% dedicated to vertical tomatoes/cucumbers (~300 ft²)

- 25% for salad greens and microgreens (~250 ft²)

- 20% for herbs and peppers (~200 ft²)

- 15% for specialty crops (ginger, starts, etc.) (~150 ft²)

- 10% for paths and work space (~100 ft²)

All crops are grown simultaneously throughout the year, with seasonal adjustments for optimal production. Layout can obviously be adjusted based on personal preferences and desire for consumption vs sale to markets.

Annual Production Breakdown (Concurrent Growing)

Conservative Estimates

Assumes basic management, minimal supplemental lighting, and accounts for seasonal variations:

- Microgreens & Salad Greens (250 ft²): 400-500 lbs/year

- Based on 5-6 oz per 10"×20" tray every 2 weeks

- Single-tier production with natural light

- Tomatoes (150 ft²): 600-800 lbs/year

- 20 lbs per plant average over growing season

- ~30-40 plants in allocated space

- Cucumbers (150 ft²): 400-450 lbs/year

- 20-25 lbs per plant per cycle

- 2 succession plantings

- Peppers/Herbs (200 ft²): 250-300 lbs/year

- Specialty Crops (150 ft²): 100-150 lbs/year

- Includes ginger, turmeric, nursery starts

Conservative Total: ~2,350 lbs/year

Moderately Intensive Estimates

Assumes good management practices, some LED supplementation, and optimized growing techniques:

- Microgreens & Salad Greens (250 ft²): 800-1,200 lbs/year

- Multi-tier production (2-3 levels) with LED lighting

- Industry example: 50 lbs every 2 weeks from 60 sq ft using 4-tier racks

- Tomatoes (150 ft²): 1,000-1,200 lbs/year

- 30 lbs per plant with extended season

- Vertical training and pruning optimization

- Cucumbers (150 ft²): 600-750 lbs/year

- 30 lbs per plant per cycle

- 2-3 succession plantings with careful timing

- Peppers/Herbs (200 ft²): 400-500 lbs/year

- Densely planted with succession planting

- Specialty Crops (150 ft²): 200-250 lbs/year

- Optimized varieties and timing

Moderately Intensive Total: ~3,500-4,000 lbs/year

Production Summary

Note on estimates: These figures are intentionally conservative and based on standard industry yields. Commercial operations with optimal management often achieve significantly higher yields. For example, greenhouse cucumbers can produce 20-30 pounds per plant over a 4-month harvest period, and experienced tomato growers achieve 6-8 lbs per square foot annually.

The geothermal mass system works by circulating greenhouse air through the 1,764 cubic feet of crushed stone behind the north wall. During sunny days, warm air is drawn through the stone, heating it up. At night, cool air passes through the warm stone mass, picking up stored heat. This passive system can maintain temperatures 20-30°F warmer than outside conditions, enabling year-round production even in harsh winter climates.